Sequence of operations

- Description

- Breakdown of production costs

- Set-up time / piece time / throughput time

- Functionality

- Related topics

- Technical documentation

Description

A work plan consists of individual work sequences or operations. This module is used to record individual work sequences, i.e. work sequences that are only to be carried out at the workstation/resource specified in this work sequence. Only the set-up time and the piece time can be entered as a formula - and therefore variable.

If a sequence of operations is to be defined variably with regard to the workstation/resource, a conditional sequence of operations can be inserted into the work plan.

Distribution or calculation of production costs

In principle, the production costs for a part are divided into two differently valued parts:

Labour costs and material costs

As a standard, the additional costs incurred in addition to wages and materials, e.g. for purchasing or stock management of the required parts, are included in the overheads. These are stored globally in the client.

However, the following approach is preferable in order to be able to calculate production costs precisely according to other costs incurred during production, such as machine running costs and programming costs, without having to include all costs invisibly in overheads:

In the part or at the work plan position, a material characteristic must be defined which contains the costs for e.g. the machine costs per hour according to the following format

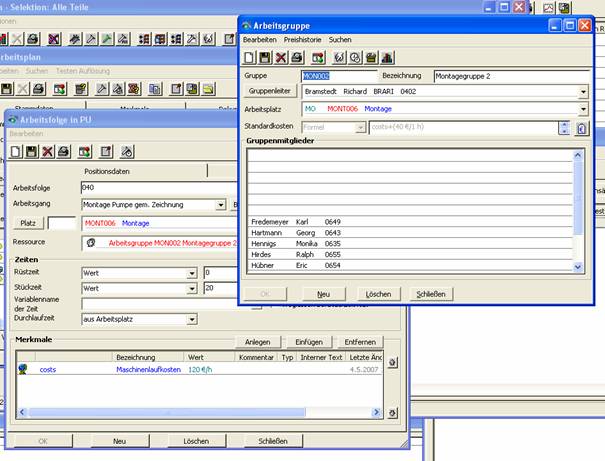

costs = 120€/h (see below in the picture in the work sequence)

You must therefore create a material characteristic for each cost element.

The characteristic can also be stored directly on variant parts and calculate itself from other constraints (calculated or conditional characteristics).

To be able to take these costs into account, a formula in the resource of the work sequence is necessary (in the picture the standard costs of the working group):

Standard costs = formula = costs+(40€/1h)

Since the formulae do not know any compound units, instead of 40€/h --> write 40€/1h and put this in brackets.

The machine costs per hour specified via the material characteristic are now added to the standard machine costs per hour.

In order to check whether the costs are actually there without any error occurring, the formula can be extended by a query as follows

(if(has(costs))costs else (0?))+(40€/1h)

In this case, the system queries in advance whether the costs have been found and otherwise uses the value 0?, whose unit is based on the next component for further calculation.

In the parts precalculation we then immediately see the result:

The marked line is our work sequence, which has received wage costs of 1.600€ for 600 minutes (10 hours) (120€ machine running costs + 40€ standard costs = 160€ per hour * 10 hours = 1600€)

Set-up time / piece time / throughput time

The times can be given as a value, formula or conditional table in the parts list.

- Value is an absolute time value, e.g. "5 min".

- Formula - Times can be calculated with a calculation formula. For example, you can access the quantity of the exploded BOM item with "transaction.Amount()". The following example calculates a setup time of 30 min. per 250 litres of the exploded item.

- Conditional table - This can be used to define times that cannot be represented in any continuous function (formula), e.g.:

Condition Formula transaction.Amount()>50Pieces 1min transaction.Amount()>25pcs 3min 10min

Examples of values that can be used in a formula or condition in the sequence of operations:

| Access printout | Description |

| this.amount.Amount() | Piece time of the work sequence |

| this.baseAmount.Amount() | Set-up time of the work sequence |

| transaction.Amount() | Quantity of the parts list |

| transaction.object.uniqueID | Part number of the parts list |

Functionality

This window is used to maintain individual work sequences or operations. You can select a sequence directly by entering the desired sequence number in the sequence field and confirming with RETURN.

To show that this sequence of operations is an external production you have to select a supplier under resources. In addition, a unit of performance that represents this external performance and must be defined at the supplier. In this case of external production there are several rules to be observed, so that e.g. the deregistration of the PDC hours but also the preliminary costing of parts runs smoothly:

A further description of external production within the work plans can be found here.

The second tab "Document directory references" allows you to link the position to document directories. A document could thus serve as a quality assurance instruction, for example.

Input window

| Menu item | Description |

|---|---|

| Edit | - |

| : Validity | Set validity |

| : Work plan header | Call up the input window for the work plan of the current work sequence |

| Close | Close window |

| Symbol | Description |

|---|---|

| Create new work sequence | |

| Save changes | |

| Delete work sequence | |

| Print work sequence | |

| Set validity | |

| Create/edit notes | |

| Call up the input window for the work plan of the current work sequence |

| Field | Description |

|---|---|

| Position data | |

| : Sequence of work | Number of the work sequence. The formatting can be specified by the CX_JOB_SCHEDULE_ITEM counter. It is also possible to set a counter with this counter. By default there is no counter and the formatting is preset with "000" "000". |

| : from index | Index of the work sequence |

| : Operation | This group is displayed when editing work plans, the following group "Production area" is then hidden |

| : : Operation | Operation Description |

| : : Order roll | Assignment to an ordered article, if the work sequence is external production (extended workbench) |

| : : Place | Assignment to workstation |

| : : Resource | If a workstation has been selected to which resources such as machines, work groups or suppliers have been assigned, they can be selected in this field |

| : Production area | This group is displayed when editing resource plans, the previous group "Operation" is then hidden |

| : : Area | Assignment to a production area |

| : : Process | Explanatory text, which process has to be carried out in the production area |

| : : Resource | If a workstation has been selected to which resources such as machines, work groups or suppliers have been assigned, they can be selected in this field |

| : : Date control | Here you can specify whether the resource should be given special attention in its further use (e.g. printed on "appointment cards" or similar) |

| : Times | - |

| : : Setup time | Set-up time to complete the sequence of operations. See |

| : : piece time | Unit or individual time per yield. See |

| : : Variable names of the time | In this field the total time of the work sequence can be assigned a variable name in order to be able to use this total time in further calculations |

| : : : Omitted for zero piece time | Identification whether the work sequence should be ignored if the piece time is zero: e.g. if the piece time is calculated using a formula |

| : : Lead time | Direct entry of the throughput time of this sequence of operations or marking that the throughput time of the workstation generally applies. See |

| : Features | - |

| : : List of characteristics | List of characteristics to describe the operation (e.g. technical) more precisely |

| Texts | |

| : Free text | Freely definable, multilingual text |

| : Text modules | |

| : : Create | Creating a local text module |

| : : Insert | Inserting a global text module or a global condition group |

| : : Remove | Remove the text module selected in the list of text modules |

| Documents (For an additional description of the assignment of documents, click here) | |

| : Structure tree | Using the structure tree on the left side, subfolders or subnodes( (At present only document references can be structured). |

| : List | On the right-hand side is the list of document references. The local document references are marked with the little house symbol ( link: Description of the buttons for maintaining the assignments to the document references |

| Description of structure node | For the folder (structure nodes) defined in the structure tree, a different description can be entered here and saved using the save button to the right of the field. |

| button | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Documents | |||||||||||||||||||||||

| Open | Opens the document of the selected document reference in the preview. Depending on the file type, Adobe Acrobat Reader, Word or, for example, Internet Explorer is started. | ||||||||||||||||||||||

| Insert | When inserting, you can choose between local document references and global document references.

| ||||||||||||||||||||||

| Edit | The document reference can be edited in its edit screen. | ||||||||||||||||||||||

| Remove | If a global document reference is selected, the link between the document reference and the part is broken. Local document references are deleted. | ||||||||||||||||||||||

| Status bar | |||||||||||||||||||||||

| OK | Changes to the operating sequence are saved. If no changes are made, the button is locked. | ||||||||||||||||||||||

| New | The input window is cleared. | ||||||||||||||||||||||

| Delete | The displayed work sequence is deleted. | ||||||||||||||||||||||

| Close | The window is closed without saving changes. If you want to save the changes, you must press the "OK" button. | ||||||||||||||||||||||

Related topics

Technical Documentation

Overview

Individual allocation of basic module

Module name

allocsng.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| EDIT_SINGLE_ALLOCATION | NULL or single allocation object | Call up input window for individual allocation |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| EDIT_SINGLE_ALLOCATION | NULL or single allocation object | Call up input window for individual allocation | Single Allocation Editing Module |

| EDIT_VALIDITY_BY_DATE | Window title, object, recipient of the reply | Call up the input window for validity | Validity Editing Module |

| SINGLE_ALLOCATION_CHANGED | Single allocation object | Individual allocation was changed | |

| SINGLE_ALLOCATION_CREATED | Single allocation object | Individual allocation was created | |

| SINGLE_ALLOCATION_DELETED | Single allocation object | Individual allocation was deleted |

Work sequence editing module

Module name

jobssing.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| ATTRIBUTE_SELECTED | Attribute object | Attribute was selected | |

| COMMENT_CHANGED | Object | Comment has been changed | |

| DELETE_JOB_SCHEDULE_SINGLE_ENTRY | Work plan entry object | Delete routing entry object | |

| EDIT_JOB_SCHEDULE_SINGLE_ENTRY | NULL or routing entry object | Call up the input window for work plan entry objects | |

| EDIT_SINGLE_ALLOCATION | NULL or single allocation object | Call up input window for individual allocation | |

| WORK_STATION_SELECTED | Workplace object | Workstation object was selected |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| EDIT_COMMENT | Object | Open the input window for comments | Comment editing module |

| EDIT_JOB_SCHEDULE | Work plan object | Call up the input window for work plans | Work plan editing module |

| EDIT_JOB_SCHEDULE_SINGLE_ENTRY | NULL or routing entry object | Call up the input window for work plan entry objects | Work plan entry editing module |

| EDIT_SINGLE_ALLOCATION | NULL or single allocation object | Call up input window for individual allocation | Single Allocation Editing Module |

| EDIT_VALIDITY_BY_DATE | Window title, object, recipient of the reply | Call up the input window for validity | Validity Editing Module |

| JOB_SCHEDULE_SINGLE_ENTRY_CHANGED | Work plan entry object | Work plan entry was changed | |

| JOB_SCHEDULE_SINGLE_ENTRY_CREATED | Work plan entry object | Work plan entry was created | |

| JOB_SCHEDULE_SINGLE_ENTRY_DELETED | Work plan entry object | Work plan entry was deleted | |

| SELECT_ATTRIBUTES | NULL or Collection attribute objects | Call up the selection window for attributes | Attribute selection module |

| SELECT_WORK_STATION | NULL or Collection workstation objects | Call up selection window for workstations | Workstation selection module |

| SHOW_PREVIEW | Widget | Print Preview | Print Preview |

| SINGLE_ALLOCATION_CHANGED | Single allocation object | Individual allocation was changed | |

| SINGLE_ALLOCATION_CREATED | Single allocation object | Individual allocation was created | |

| SINGLE_ALLOCATION_DELETED | Single allocation object | Individual allocation was deleted |